Enhancing Multi-Disciplinary Optimization by Initial Systematic Screening

Enhancing Multi-Disciplinary Optimization by Initial Systematic Screening

Mikael Törmänen

Volvo Car Corporation – SWEDEN

Curriculum

Dr. M. Törmänen finished his Ph.D. in Vehicle Engineering in 2001 at the department of Machine and Vehicle Systems at Chalmers University of Technogy.

He has joined Volvo Car Corporation in 2005 to work with powertrain simulations with focus on the longitudinal vehicle dynamics, i.e. driveability. In June 2012 he was appointed a position as Technical Expert MDO & Powertrain Attributes Balancing.

Since the attribute driveability is influenced by almost every mechanical systems in the front-end of the vehicle he has gained a broad overall system knowledge and experience in different customer attributes that need to be optimized. To improve the optimization between several attributes he has formed a CAE framework that makes it possible to reuse and speed up the optimization process. This has been applied on engine mount systems which has a major impact on driveability. Since 2007, the main optimzation tool has been modeFRONTIER.

Abstract

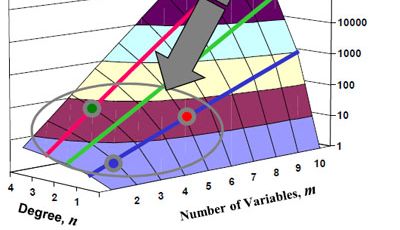

Today we are seeing a growing usage of optimization tools in decision making. At the same time we recognize that the optimization tasks are increasing in complexity. When the complexity of a system becomes high enough it will be difficult to find an optimum solution with normal hands-on methodology, and if succeed it will, surtainly, take lots of time and effort. The main factors for this is the number fitness functions and their complexity, i.e. degree of non-linearity, discontinouties, etc., as well the set design constraints covering the overall design requirements, e.g. durability, manufacturing, customer attributes etc. When all these are put together this might generate a design space that could be hard to explore for an optimization algorithm. This paper presents one way of dealing with this kind of problems by making use of the great experience that is held by the designers and systems engineers. This engineering experience has been evolved during many years and could be used effectively to reduce the complexity of the optimization problem by means of axiomatic design. Using real-world knowledge, the system attributes and inputs are decoupled as far as possible reducing the system into a triangular form. Thus, the problem can be systematically splitted up into a number of sequential phases of screening, cf. gaussian elimination when solving linear equation systems. During the screening the input parameters and attributes are clustered into smaller subgroups decreasing the design space significantly and, thereby, enabling the usage of fitness functions with higher fidelity level, i.e. longer computation time. The final outcome from this is a set of feasible designs that could be used as a starting population for global optimization. This approach has been used with success at Volvo Cars resulting in great improvement of the optimization of engine mount systems. This new method provides optimum solutions faster, shortening the development time from months to weeks. By applying system information into a complex optimization task it will have a multiplicative effect on the optimization, especially, when dealing with highly non-linear effects. The number of design evaluations are significantly decreased since the design space is much smaller. This in turn enables the usage of higher order numerical methods providing better precision to the design evaluations. All designs that comes through the initial screening are feasible providing a good starting point for an optimization.