Fluid Structure Interaction of a rigid body: simulation of a floating device used to detect the liquid level inside the filling system of a packaging machine

Apparuti Daniele - Tetra Pak (Italy)

PRESENTATION

Abstract

Tetra Pak develops automatic machines for packaging sterile and shelf-stable liquid food product using a paper based and multi layer packaging material. The forming process of Tetra Brik containers is a very complex procedure that includes serialization of the packaging material, folding and forming of the pack, filling with liquid product and aseptic sealing to protect the food from external environment. The complexity is further increased by the fact that all the operations has to be realized in a sterile environment at high speed and the current market need is to package at least 15000 litres per hour by a single machine.

In similar machinery the possibility to measure performances at specific point has always been critical therefore the usage of computer aided engineering is widely spreading to further optimize and develop the system.

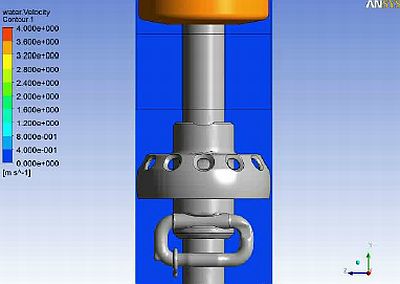

For example the current work describes the fluid dynamic model built to simulate the milk flow inside Tetra Pak filling system where, due to the complexity of the geometry and to the fact that the environment must be kept sterile, it is almost impossible to install sensor to measure pressure and flow rate.

The CFD simulation developed includes moving mesh strategy and rigid body model to account for moving object and a multiphase VOF method is employed to resolve the free surface of the food product and its interaction with a floating device used to monitor the liquid level in the machine.