Optimization of a press for sealing of new photovoltaic modules

Antonini Alessio - Daunia Solar Cell (Italy)

Accarino Marco - EnginSoft (Italy)

PRESENTATION

Abstract

Differently from traditional solar cells, mainly based on the exclusive use of semiconducting materials at solid state, new generation photovoltaic cells – Dye sensitized solar cells (DSSC) are characterized by electric energy production caused by a photoelectrochemical reaction of oxidation-reduction (redox) triggered by solar energy absorption by dye-sensitized. DSSC can be sealed using glassy materials that have to undergo a vitrification cycle (pressure in temperature).

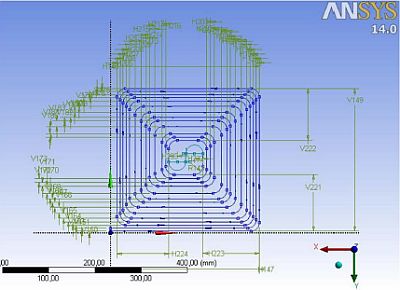

Such action can be performed by a press with heating plates that can simultaneously press and heat the DSSC. The objective of this activity has been the analysis and further optimization of a Daunia Solar Cell press for DSSC sealing. In particular, the optimization has been focused on the geometry of the heating pipe coil within the press die in order to guarantee an homogeneous heating of the DSSC press during the sealing process. The activity has been developed in two phases: CAD modeling, FEM model creation and press set-up in phase one – Optimization analysis of the press starting from the FEM model investigated in phase 1 so to obtain an even temperature field on the die and therefore and even sealing of the DSSC device.

The optimization of the press die has been possible thanks to the integration of design and optimization techniques in FEM computation.

In particular Design Modeler (CAD model) and Mechanical (transient thermal simulations) have been used in phase 1 and the FEM parametric model of ANSYS WorkBench has been implemented in in modeFRONTIER optimization software in phase 2, so to get an optimum design.

modeFRONTIER is a advanced optimization software, which is based on enhanced algorithms, and it can provide an additional value to experience and allows to both increase quality and speed up the product design and development.

A peculiar aspect of this activity has been the variable number that modeFRONTIER has had to assign and optimize, including pipe coil geometry, type of material to be used, thicknesses and die size.

In conclusion, the die has been produced, following modeFRONTIER output and we have experienced an improvement as expected by the optimization analyses.