Air intake manifold design: a geometrical dimensioning for engine performances optimization

Teducci Assunta - Magneti Marelli (Italy)

PRESENTATION

Abstract

The task of the air intake manifold is to provide the air that satisfies the requirements of the engine over its operating regime. Intake manifolds consist typically of a plenum with individual runners feeding branches which lead to each cylinder: as consequence, the engine performances as power, torque and efficiency are strictly connected to the geometry and behavior of our products.

The design process is a complex flow where different tools work together to obtain the geometry of the air intake manifold that lead to the engine performances required by the customers: it is not a simple process due to the different fluid dynamics needs, to the geometrical constraints and to the conflicting target of performances.

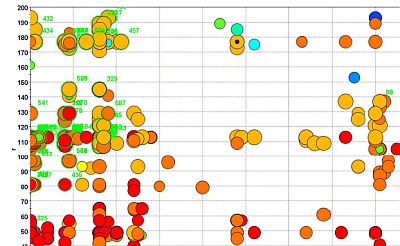

A multi-objective optimization with modeFRONTIER has been carried out, by integrating in the design workflow a 1D software, to optimize the main engine performances (torque and power), and a 3D CFD software, in order to further improve the best solutions optimizing pressure drop, flux homogeneity, etc.