Bringing the power of expert CAE software to spread-sheets: Solutions for the study of hydropower plant performance using Flowmaster and Excel

Kjeldsen Morten - Flow Design Bureau AS, FDB (Norway)

PRESENTATION

Abstract

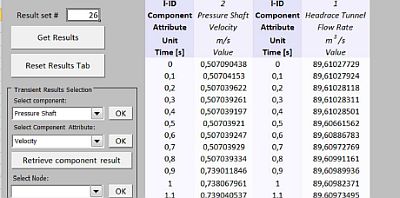

In cooperation with Jarle V. Ekanger (FDB) and Prof. Torbjørn K. Nielsen at the Norwegian University of Science and Technology(NTNU). FDB is a consultancy and technology development company that uses high level software for a wide range of purposes in process-, fluids-, measurement- and control engineering. In 2009 FDB started to represent Flowmaster in Norway, and with a particular emphasis on the O&G business. In addition to O&G, FDB also has a focus on the Norwegian hydro-power business. The typical Norwegian hydropower plant consists of a number of reservoirs, (rock excavated) tunnels and pipes and turbine units. Most of the larger of these plants were commissioned during or before the 1980s. The typical upgrade scenario is the replacement of turbine units, and the occasional expansion of tunnel cross-section areas in order to increase maximum flow rate and to reduce the head-drop. While serving Flowmaster O&G clients it became evident to FDB that using spread-sheets, such as MS-Excel, could be beneficial for certain engineering organizations. The benefit was exemplified by the fact that parametric studies on a topologically locked flow network is of interest to complete also for other groups of engineers than those originally designing the network. By topologically locked it's meant that the number of elements and their relative position is fixed, but that the properties of each element can change. Prof. Nielsen, at the Fluids Engineering group of the Norwegian University of Science and Technology, has developed an analytical method for generating turbine characteristics. The method is based on the Euler turbine equation, or the conservation of angular momentum, and allows the generation of Suter curves for various guide vane openings of the turbine unit. The accuracy of the model is only superseded by the turbine manufacturers model testing and/or 3D CFD over a whole range of operating points. Based on Nielsen's work Mr. Ekanger has programmed a Flowmaster element that incorporates the Nielsen turbine-element, as well as allowing for measured and/or supplier's data. Starting from version 7.9 Flowmaster has included a non-GUI solver license. Such a solver license will allow the calculation of Flowmaster based networks through MS- Excel, but without the possibility of manipulating the topology of the network. In hydropower the topology of the hydraulic conduits are usually fixed, while the studies are limited to adjustments to existing conduits but with a greater emphasis on the replacement of a turbine unit. All combined FDB has identified a business case in which FDB can deliver a spread-sheet where all plants for a given producer can be found in separate tabs. Certain modification can be given on selected input parameters, while the turbine characteristics can be modified using suppliers or Nielsen's turbine data. The user of the spread-sheet can now calculate production scenarios and the economy for replacement of turbine runners; and all the calculations are based on a proven solver for flow systems.