Rotary forging: simulations, apllications and link with microstructural calculations

Pérez Iñaki - TECNALIA (Spain)

Santos Maite - TECNALIA (Spain)

Varela Sonia - TECNALIA (Spain)

Mangas Ángela - TECNALIA (Spain)

PRESENTATION

Abstract

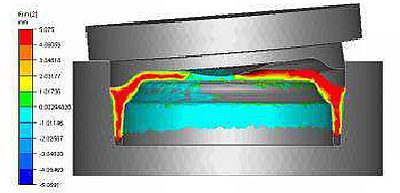

As an alternative to conventional forging, rotary forging can be used to reduce forming forces and to obtain higher deformation ratios without cracks in one step.

Rotary forging changes the conventional deformation path improving the strain ratio in one step, which enables to achieve near net shape geometries. This advantage causes the minimization of tooling costs thanks to the reduction of the number of preforms used to obtain the final component. Simulating rotary forging process is not an easy task, as involves rotary movements and long computation times. Besides, the use of this technology for non-usual materials, as Inconel718, involves microstructural calculations, whose results have been checked experimentally.